Tool Development (TTT Solution)

TOOL DESIGN

|

|

|||||||||

|

|

Tool making |

|

|

|

TOOL MAKING

| The making of tools will either be in-house or outsourced. Initial tools made will be polished, assembled and adjusted in-house by experienced engineers at Nakashimada. | ||||||

| For example, press-fitting and machining for micro-parts tools is extremely difficult, we rely on our experience with hand-finishing. An impeccable tool depends on how and how well the polishing was performed with diamond powder. | ||||||

|

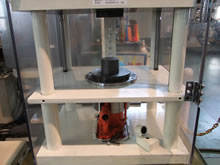

TRY OUT

| Tools are set up on the selected machine type. Our experienced engineers will work swiftly towards setting up the machine according to customer’s requests. | ||||

|

Tool Development Flow

|

Product Analysis

|

●Confirmation of machine specification ●Development of new machine ●Tolerance of product size and shape ●Proposal of forging shape |

|

Product Dimension Confirmation Dimension Confirmation

|

●Determination of shape of prototype |

|

Tool Making

|

●Progression ●Change of surrounding of tool area ●Confirmation of special options |

|

Confirmation of

product size

|

|

Tryout

|

| Sample submission, approval, machine shipment Tools will be submitted together with drawings |

Click here for more tool development projects