What are Headers and Parts formers?

|

|

Here are the processes.

| (1)Wire Cutoff | (2)Area Reducing (forward extrusion).. Size reduced. | |

| The wire is cutoff at a calculated length. | ||

|

|

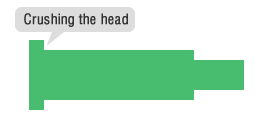

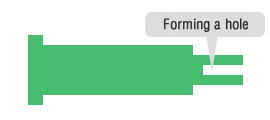

| (3)Crushing the head(Preform).. Head forged. | (4)Forming a hole(backward extrusion) | |

|

|

| Tools are used to form various products. By modifying the shape of the tools, we can form products like nails, bolts and special parts. By providing tool development, Nakashimada has helped many customers form parts that were not possible by cold forging before. |

| In addition, Nakashimada has developed some original mechanism to widen the applications for headers. |

| [ Fingerless Transfer] We have developed a new mechanism that leaves the blank inside the die while bringing to the next progression. It solved the problem for transferring very short, small and eccentric parts that were not possible with conventional fingers. As such, blurring and turn is controlled improving drastically the precision of the parts. Many other shapes can also be formed in this way. |

| We have die shift mechanism that dies slide horizontally. And punch shift mechanism where punches move vertically. |

Slide Die Shift

After cutoff, blank is left in the cutoff die and pass to the next progression.

Very thin micro parts below dia. 2 mm could only be made by machining before because they are very difficult to hold with fingers. Not only our new mechanism solved this problem but also it achieves extremely high precision during the process.

Punch Shift

After cutoff, blank is left inside the punch while moving to the next progression.

NP series (2D3B) machines carry this Punch Shift mechanism.

Pulse Dial (Patented)

|

Ram can slide back and forth by simply adjusting a dial on hand. Ram needs fine adjustment during setup. Pulse Dial enables the machine to move slowly and safely with much ease, reducing operator’s burden and work time.

|

|